Biogas and Bioreactors

Intro

Gentleman Scientist

After my initial blog posts I spent some time thinking about the direction I want this blog to take. Electronics, 3d printing, and coding are all great fun but I have found that they are best left as tools to an end goal. What I enjoy most is the pursuit of science and technology that isn’t directly available to me. I won’t be shifting away from the core idea of “Impractical Ideas”, but I will be trying to take on some bigger or more lofty projects with potential for real world use. With all that in mind, I would like to apologize for the break in content, this change in focus has made it harder to break things into complete posts. I realize now it will require small updates on the long path to various goals. This post is the first in a series to try to provide those small updates.

Biogas

One of the primary issues I would like to tackle is my personal waste. I am already an avid recycler and compost as much of my food waste as practically possible. It is possible however to gain even more from these waste products by processing them in a bioreactor or other more modern methods. When digested anaerobically by the right bacteria most biomass can produce methane. Many places in the world already have industrial plants producing significant amounts of power from this process, but I wanted to explore it for myself on the scale that my waste products exist.

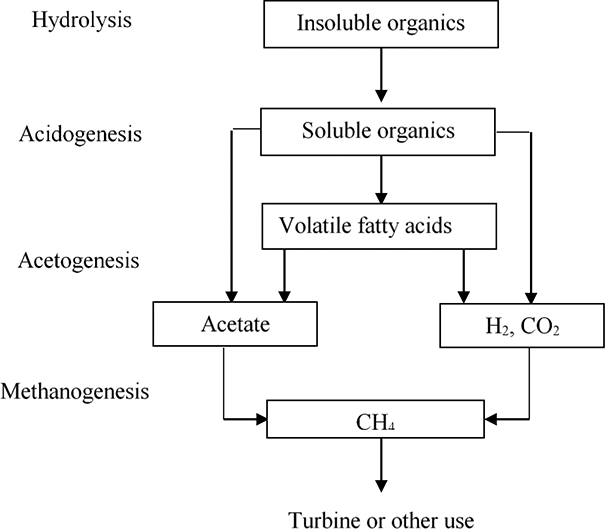

Credit to Venko Beschkov

Goals

Inputs and outputs

I like to create a sort of map of how the world works in my head. When I learn a new piece of information I often spend time digesting it to figure out where exactly in that map it fits in. Biogas fits into both the carbon and nitrogen cycle. It helps break down existing biomass into soluble nitrates for plant growth and produces CO2. The methane production for biogas is really just a happy accident in that process caused by the anerobic conditions. The bacteria we select to work for us perform methanogenesis as a form of cellular respiration.

- Inputs:

- Biomass(Primarily carbon and nitrogen)

- Water

- Outputs:

- CO2

- Methane(CH4)

- Nitrates

- Trace organic compounds with things like sulfur and iron

We mostly want the nitrates and methane, but I hope to explore sulfur extraction at some point.

Scaling - forever a pain

One of the main issues in many processes is scaling. It’s the reason the buzz worthy headlines about science rarely turn into flying cars, space elevators, or massive changes in power production overnight. In most cases this means scaling the process up from the lab scale to the industrial, for us however this means scaling down. Some things are made practical only by the economies of scale. Because the reactor must operate in anaerobic conditions, the addition of new material daily or even weekly to a live reactor can cause issues. However that is the time scale my waste is produced at, so I plan to use small reactors for tests and in the future we may explore slightly larger reactors. This downscaling will put this project into “Impratical Ideas” territory pretty quickly.

Current progress

Cows and pond mud

The first step for me was to get a live culture of the rights kinds of bacteria. I don’t have my chickens since we moved into town so I had to go a bit further than my backyard. After a short drive and an awkward conversation with a local rancher I took a sample of cow manure and some mud from the watering hole in a pasture. The species we are looking for here live in the digestive tract of herbivores and also can be found in the anaerobic conditions of thick mud near bodies of water.

Coffee

While I compost most biomass I can get my hands on, I wanted something fairly consistent to test reactors. Coffee grounds have a fairly neutral Ph and are close to the ideal carbon:nitrogen ratio at 8:1. In my reading it seems to be around 25:1 but so far my initial reactor seems to be running ok. Future tests I will be trying to add small amounts of activated carbon, cardboard, and wood pulp to see if it helps.

I started by storing up roughly a weeks worth of grounds, and in my initial reactor used them directly. For the first more controlled and quantified reactor I dried the grounds first. It is important to try to remove as much of the liquid coffee as possible because it is fairly acidic and may crash the reactor.

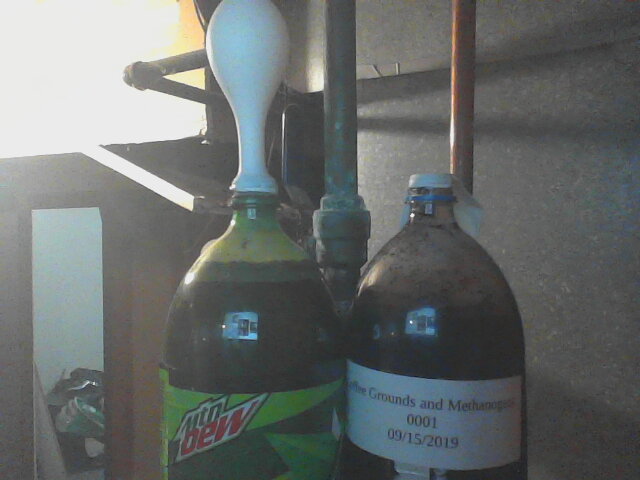

Seed reactor

All reactors so far have been 2 liter soda bottles with balloons directly on the neck. The first seed reactor was a combination of all my samples from the farm, the weeks grounds, and a small amount of spinach to add a bit of diversity in case the grounds were lacking. I started by printing a funnel that screwed directly to the bottle and emptying all the sample bags into it. When it came time for the grounds I found they were too wet and chunky, causing them to stick to the funnel. I added extra water to make it flow more smoothly and this helped but ended up overfilling the bottle. This whole process was pretty unscientific and I don’t have measurements, I basically just crammed it all in a bottle and hoped the diverse samples added would sort themselves out. It turns out evolution did a great job and they survived just fine. A few days later I had a partially inflated balloon!

Here I am testing out simple vibration to help with gas buildup in the bottom of the reactor.

Reactor 0001

I waited a week or two for the reactor to settle and the culture to establish itself well, but in this time I ran into my first issues. The coffee and mud at the bottom were too thick for the gas bubbles to escape, this causes them to expand a gross kind of foam, pushing the liquid up and into the balloon rather than the methane I wanted. I have been shaking the bottle daily to avoid this now that I am aware, but plans to automate it are already in motion.

With this established culture I could now start running more detailed tests to see what would work best. I saved another weeks worth of grounds, dried them in the oven at a low heat, and filled a clean bottle. This reactor had much more grounds than the first and after the minimal addition of water to just cover them it was about 7/8th full. I didn’t want to fill it too much considering the gas buildup issues I was having in the seed reactor. This was started on september 15th with only 20ml of unfiltered liquid from the seed reactor to start it. Its taking longer than the seed reactor but I am hoping this is only because the small amount of starting bacteria.

Warm and Cozy

Reactor temperature is an important variable I lack the equipment to regulate properly. It is also one of the reasons biogas production has seen more use in tropical climates like india. For now the reactors are sitting on top of my water heater which is somewhat ironically heated by natural gas. As things progress I am working towards a heated chamber with vibration to help with the gas buildup in the feedstock.

Closing notes

This project is far from complete and really I am just getting my toes wet into more serious biology projects. My language and general knowledge in this area is pretty lacking but hopefully I didn’t put my foot in my mouth too hard. Another issue I am running into with many of the projects I’m working on is a lack of equipment. Some of the larger pieces I plan to build and document on the blog, but simple things like a thermometer and scale are really needed to improve my process. Hopefully this post was at least mildly informative or inspired you to read more about biogas and other bioreactor uses.

Let me know what you think of this article on twitter @BohemianHacks!

If you really liked it please consider buying me a coffee

or sending bitcoin: 1JLRwwfTiqnDVz85WkeAg4fm8A6pphNcFk